3 Pool Cue Joint Types (2025 Comprehensive Listing)

The pool cue joint is a crucial component that determines how the two main pieces, the butt and the shaft, connect. This simple part significantly impacts the cue’s feel, performance, and aesthetics.

As technology and materials evolve, so too do joint designs. This 2024 comprehensive listing will delve into the three most common pool cue joint types: stainless steel, wood-to-wood, and composite.

We’ll explore their characteristics, advantages, and drawbacks to help you choose the one that best suits your playing style and preferences.

What Is A Joint?

On a billiard cue, the joint is the specific area where the two main pieces – the butt (the handle) and the shaft (the thinner end that strikes the cue ball) – connect. This connection point allows you to disassemble the cue for easier storage and portability conveniently.

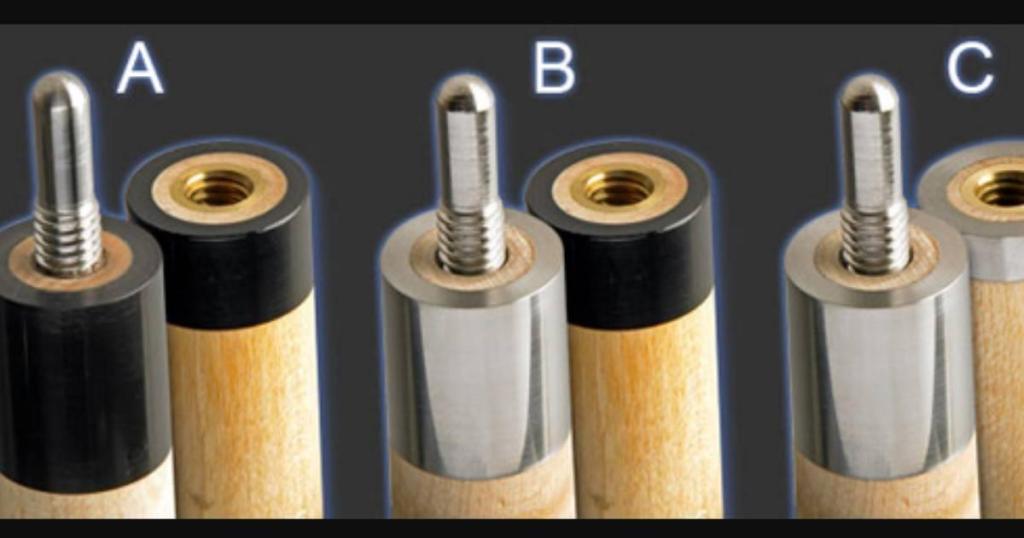

The pool cue joint typically consists of two collars, one on the butt and the other on the shaft, that interlock around a joining pin. The materials used for these collars can vary, with common options including wood, stainless steel, or even composite materials. The type of material used can affect how the cue feels and transfers energy during your shot.

But how do you measure pool cue joint size? You need to use a ruler to measure the diameter of the male part of the joint, which is the pin. It’s usually either 3/8 inch or 5/16 inch.

3 Pool Cue Joint Types You Must Know

There are 3 pool cue joint types that you should know as a beginner:

Stainless Steel Joint

These pool cue joints are known for their durability and rigidity. They provide a very solid feel between the shaft and butt, which can be beneficial for players who prefer a lot of feedback in their strokes.

Stainless steel joints are also popular for jump cues, where a strong connection is essential for transferring power to the cue ball.

However, the solid connection can produce a slightly harsher feel than other joint types. Some players may find this less comfortable

Wood-to-Wood Joint

These joints are a traditional option offering a more classic look and feel. The joint is created by simply fitting the tapered end of the shaft into a corresponding hole in the butt.

While not quite as strong as steel joints, wood-to-wood joints can still be durable. Some players also prefer the feel of a wood-to-wood joint, as it can help to absorb some of the vibration from the shot.

Composite Joint

These joints are made from synthetic materials like phenolic resin or fiberglass. They provide a good balance of strength, durability, and affordability. Composite joints can also be designed to be very low-profile, which can improve the cue’s appearance.

Frequently Asked Questions

What Joint Does Pechauer Use?

Pechauer uses two main types of joints on their cues:

- Pechauer Speed Joint: This is their proprietary design. It resembles a standard 5/16×14 joint used by many other cue brands but with some key differences.

- JP Joint: Pechauer also offers cues with the JP Joint, which J. Pechauer Custom Cues make. This is likely a licensed design and may differ slightly from the Pechauer Speed Joint.

What Is The Most Common Pool Cue Joint?

There’s not one common pool cue joint because many manufacturers use their own proprietary designs. However, certain types of joints are widely used across various brands:

- 5/16×14 joint

- Radial Pin Joints

- Stainless Steel Joints

Are There Different Types Of Pool Cues?

Different pool cues are available depending on the game you’re playing. The most common differences are:

- The cue’s tip width.

- The material used for the ferrule (the ring that reinforces the tip).

- The type of wood used for the cue.

What Joint Does Mezz Cues Use?

Mezz D2 joint system is Miki’s original quick-release joint which takes approximately two turns to secure the shaft to the butt. The D2 joint is an innovative joint technology using the trapezoid screw construction, and it is the most effective mechanical structure for a quick-release joint system.

Conclusion

The ideal pool cue joint types depend on personal preference and playing style. Stainless steel joints reign supreme for players prioritizing a solid feel and maximum power transfer. A wood-to-wood joint might be your perfect match if you value a classic look and feel with a touch of vibration dampening.

Composite joints offer a compelling option for those seeking a balance of affordability, durability, and a modern look. Ultimately, the best way to choose is to try out cues with different joint types to see what feels most comfortable and delivers your desired performance.

So, rack up your favorite game and enjoy perfecting your shot!

Dave Pearson

Dave Pearson, the world's leading pool entertainer, is renowned globally as the ultimate exhibition player.

Boasting 20 world records endorsed by the prestigious Guinness Book of World Records, Dave established a legendary history in the sport industry.